Roubaix, France

Vertical cotton farming engineered for urban labs

Crop Urbanis developed vertical infrastructure, environmental controls and harvest workflows to grow cotton indoors in northern France while preserving fibre quality.

Project overview

A textile innovation lab wanted to explore indoor cotton production to shorten supply chains and demonstrate sustainable fibre cultivation. Crop Urbanis handled engineering and agronomy design.

Challenges & approach

- Cotton requires precise photoperiod, heat and humidity not typical in northern France.

- Mechanical harvesting inside vertical racks needed ergonomic and fibre-safe workflows.

- Project demanded quantifiable water and energy savings to justify R&D investment.

Our contribution

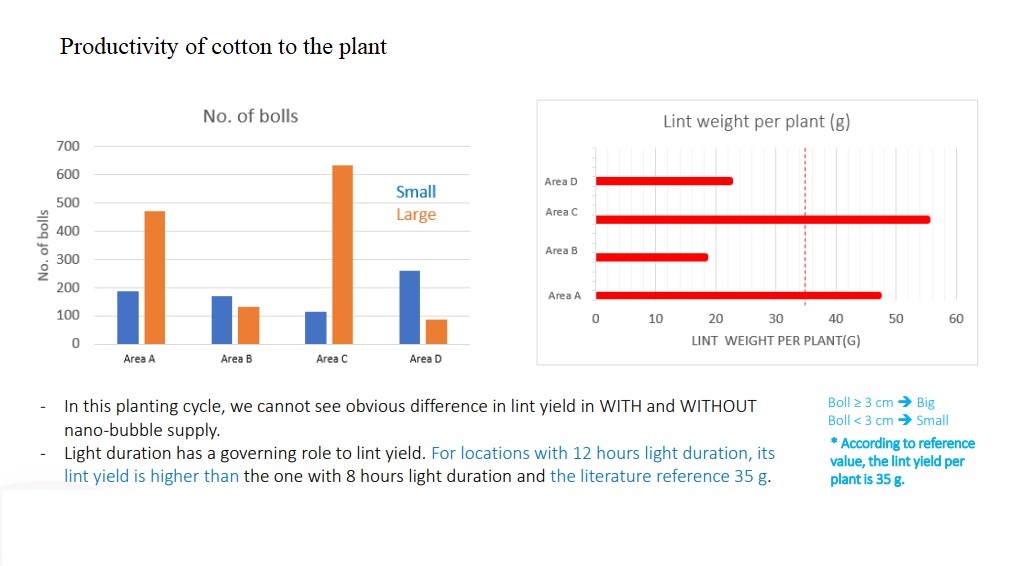

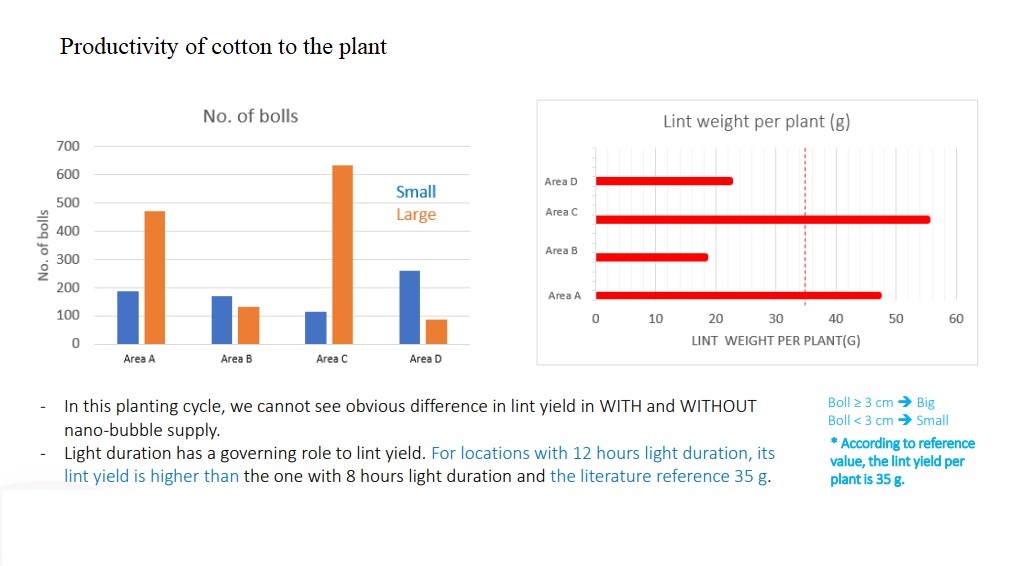

- Engineered climate zones with LED spectrum tailored to cotton flowering and boll development.

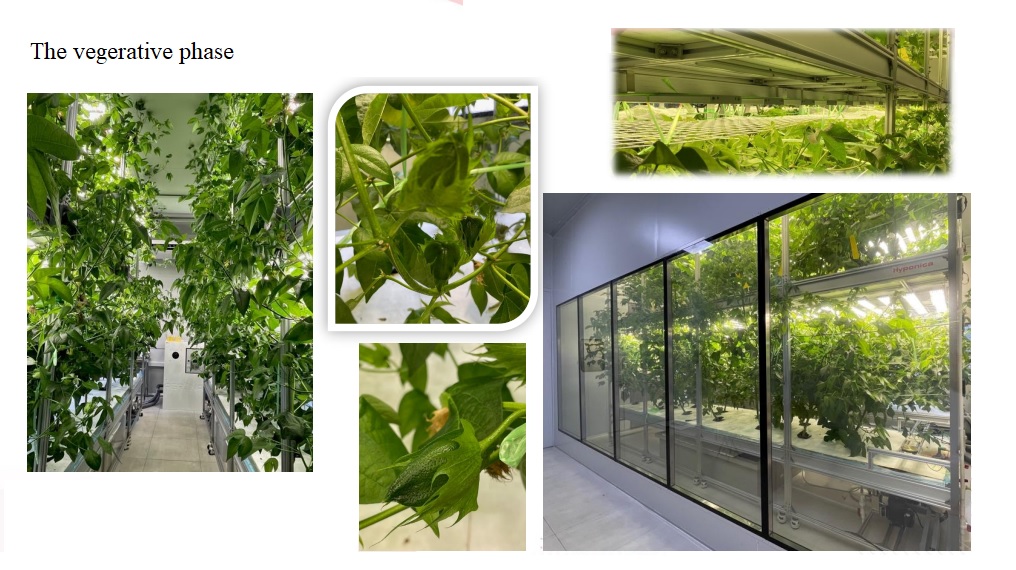

- Designed modular racks with adjustable picking arms and lint capture systems.

- Modelled water recirculation and energy loads, demonstrating sustainability metrics for stakeholder buy-in.

Outcomes & proof

| Metric | Result | Context |

|---|---|---|

| Trial plan | Delivered | Growth stages + targets |

| Nutrient guide | Delivered | Cotton-specific |

| Observation checklist | Delivered | Weekly log |

Inline FAQs

Is vertical cotton commercially viable yet?

This prototype validates feasibility; commercial rollout requires further scaling studies which are outlined in the dossier.

How do you manage lint and dust indoors?

The racks include filtration and air handling SOPs to capture lint and maintain air quality.

Project gallery